Precision Position Detection

Pressure sensors can be used to recognize precise pressing positions. This is not possible with a single sensor, but position tracking becomes possible when multiple sensors are arranged.

Position Detection Principle

Basic Conditions

- Arrange multiple sensors to measure pressure distribution

- Detection accuracy decreases with larger gaps between sensors

- The pressing area must be larger than the sensor spacing

- Place sensors densely and precisely where deviation typically occurs

Position Detection Precision

| Sensor Array | Sensor Spacing | Theoretical Resolution |

|---|---|---|

| 4×4 | 20mm | ~5mm |

| 8×8 | 10mm | ~2.5mm |

| 16×16 | 5mm | ~1.25mm |

| High Density | 1.2mm | ~0.2mm |

Reference Example

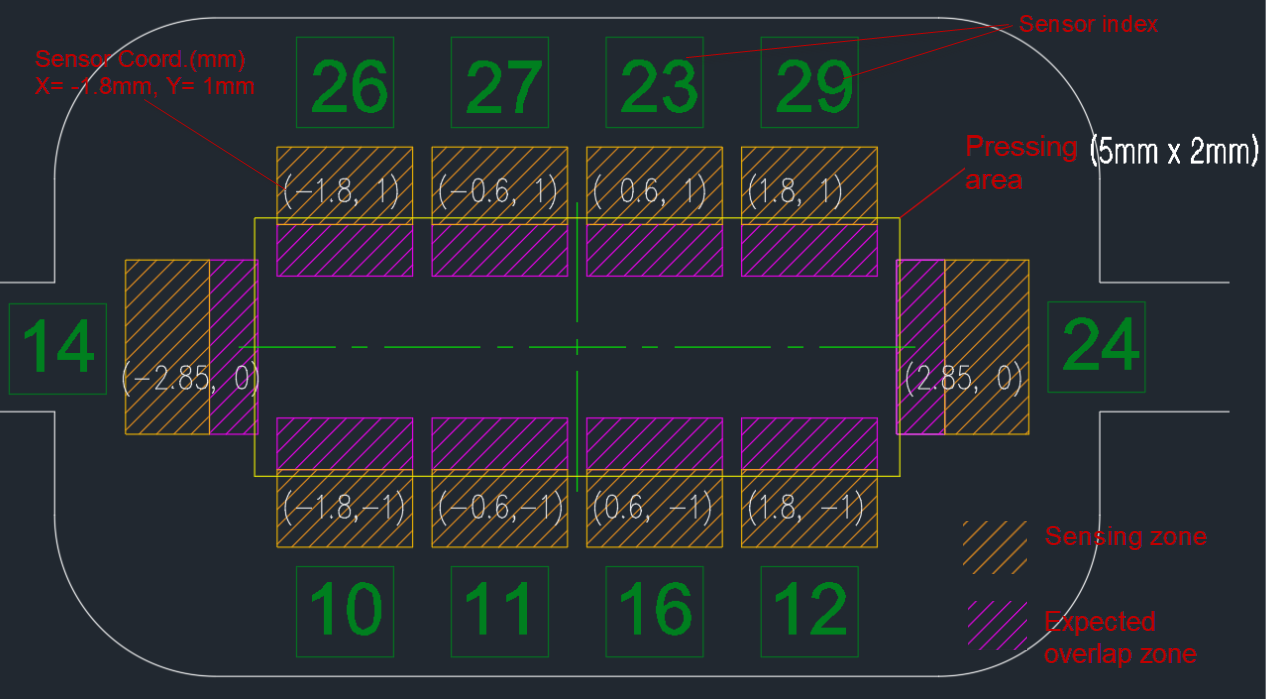

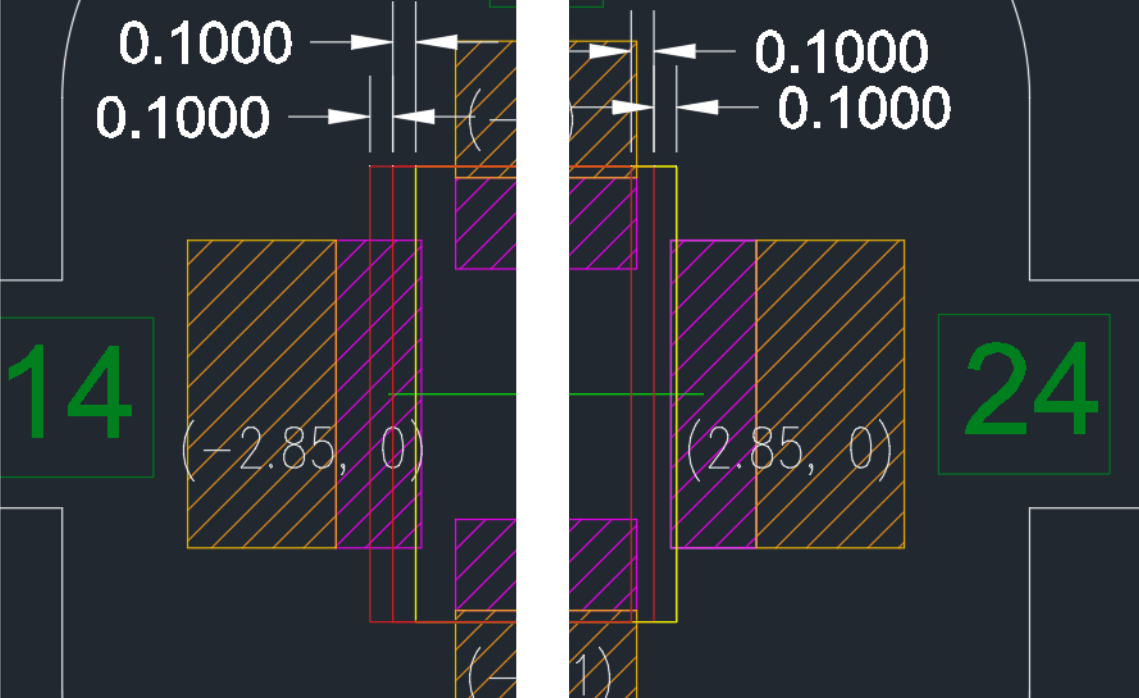

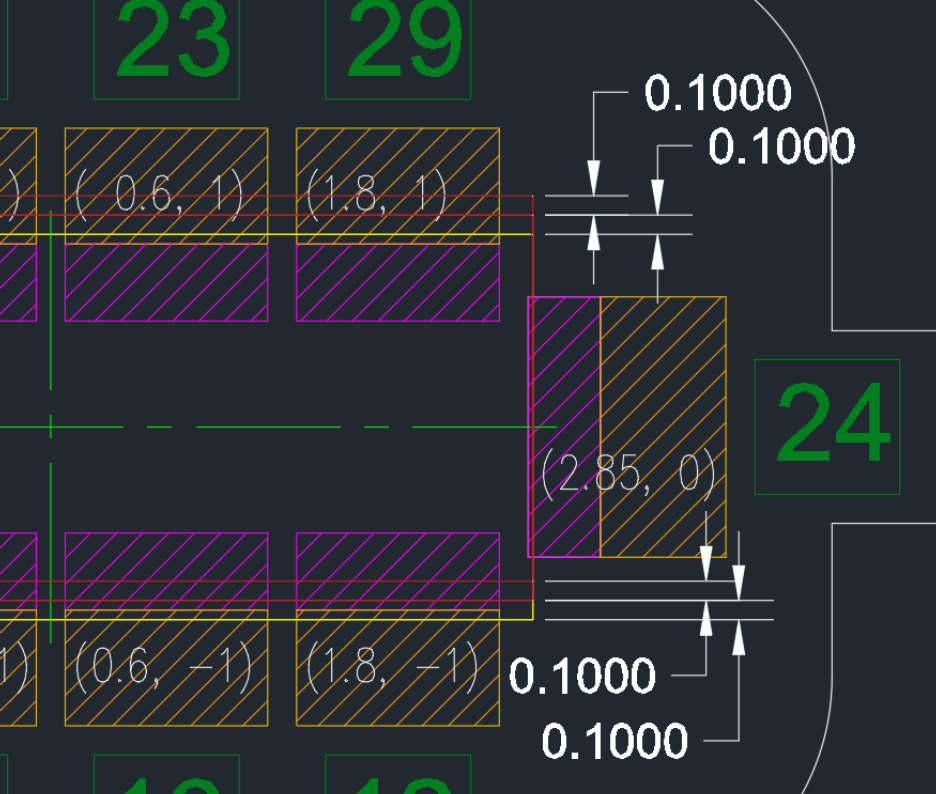

Sensing point spacing: 1.2mm Minimum deviation detection: 0.1mm

Detectable Actions

Sensor structure for detecting 0.1mm deviation and distortion in the X direction.

Sensor structure for detecting 0.1mm deviation and distortion in the Y direction.

Deviation Detection

- Detecting whether the pressure zone moves outside the sensor range

Twist Recognition

- Detecting rotation/tilting of the contact area

- Detecting which area makes contact first

Center of Gravity Movement Tracking

- Real-time tracking of contact point movement path

Contact Surface Damage Detection

- Estimation based on measurements from multiple contact points

Use Cases

Precision Pressing Equipment

- Detecting position deviation due to equipment aging

- Detecting whether deviation occurs during pressing, even when landing at the correct position

Robotics/Automation

- Verifying gripper grasping position

- Monitoring contact point alignment status

- Inspecting object placement accuracy

Medical/Healthcare

- Plantar pressure analysis (foot pressure distribution)

- Posture analysis systems

- Rehabilitation training feedback

Sports

- Golf grip analysis

- Bat/racket swing analysis

- Balance training systems

Implementation Considerations

Sensor Placement

- Must cover the entire area to be detected

- Closer sensor spacing improves precision

- Consider the trade-off between cost and precision

Sampling Rate

- Fast motion tracking: 100Hz or higher recommended

- Static position verification: 10-50Hz is sufficient

Noise Processing

- Apply moving average filter

- Prevent false detection by setting threshold values

Precautions

- Dead zones: Direct measurement is not possible in gaps between sensors (estimation through interpolation)

- Contact area: Very small contact points (such as pen tips) are difficult to detect

- Pressure threshold: Very low pressure is difficult to distinguish from noise

- Environmental effects: Consider drift due to temperature/humidity changes