Sensor Structure

Key Sensor Dimensions

Sensor Thickness

The sensor thickness is typically around 0.3mm to 0.4mm.

▲ Sensor cross-section

Depending on the application, sensors can be made thinner (down to 0.22mm minimum).

When exterior materials are included, the thickness increases somewhat.

▲ Sensor cross-section with exterior materials

Purpose of Exterior Materials

- Sensor protection and improved contact - Silicone on the top surface

- Attachment - Double-sided tape on the bottom plate

- Extending sensor measurement range - The thicker the flexible/elastic material on the top surface, the wider the measurement range.

See the Exterior Materials and Sensor Sensitivity page for more details.

Sensor Outer Border

A spacer is installed on the outer border of the middle layer for sensor assembly.

▲ Space for double-sided tape (spacer) installation

The spacer typically has a width of 2-3mm. This area cannot measure pressure.

Sensor Air Vent

Air vents are necessary for smooth sensor operation.

▲ Sensor exploded view

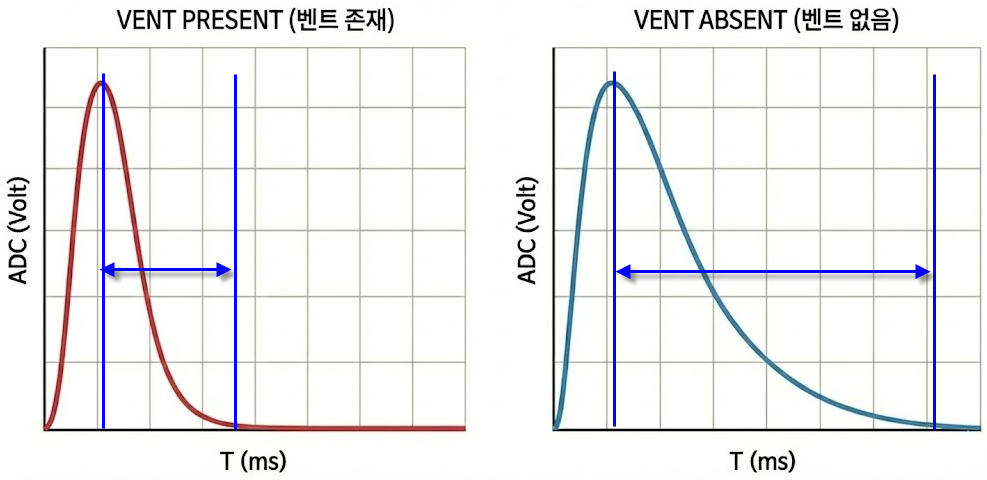

A vent width of 1-2mm is sufficient. Without a vent, sensor response becomes slower. Recovery time is particularly affected.

▲ Sensor response with and without air vent

For waterproof sensor specifications, air vents are not included. As mentioned above, in this case the sensor's shape recovery takes longer, which increases the measurement time per cycle.

Creating an internal air pocket can maintain waterproofing while reducing recovery time, but this is an exceptional case and will not be covered in this document.

Multi-channel Sensor Dimensions and Dead Zones

Multi-channel matrix sensors are effective for measuring pressure distribution over large areas.

- Sensor cell size: Sensor cells are typically square-shaped. Each side of a sensor cell is usually designed to be 4mm to 15mm. Although uncommon, cells can be made as small as around 1.x mm per side. In such cases, manufacturing costs for the sensor and measurement circuit increase.

- The matrix shape is not fixed—while typically rectangular, circular or triangular shapes are also possible.

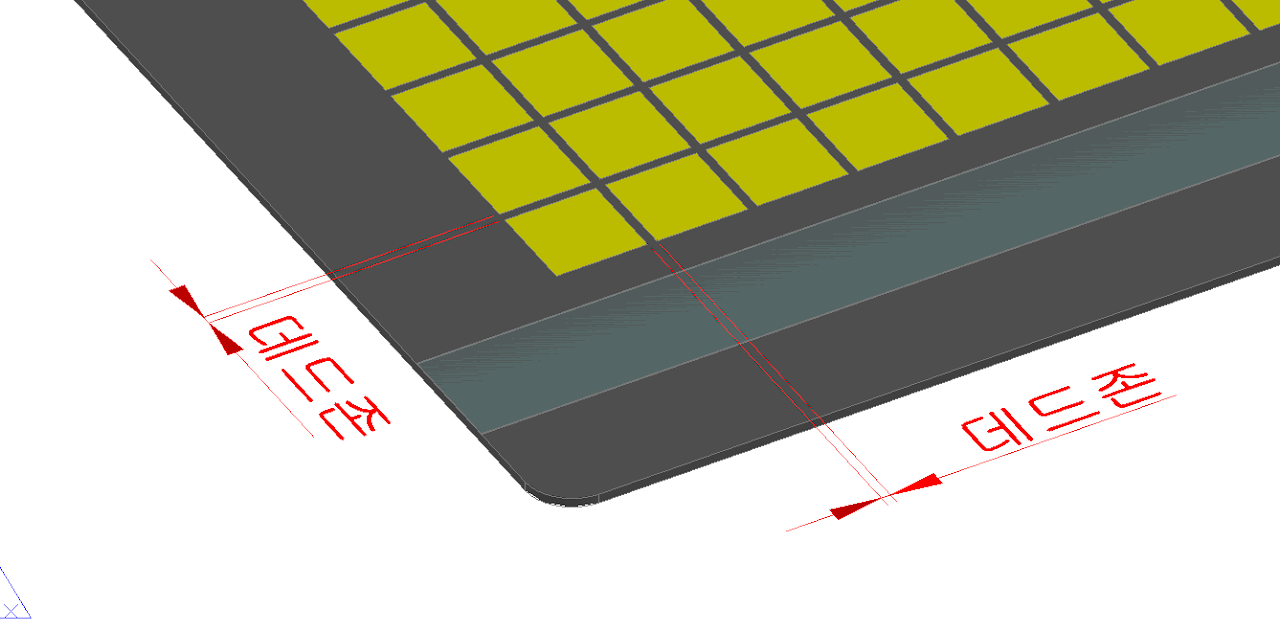

▲ Dead zones between sensor cells

The empty spaces between sensing cells (dead zones shown in the figure above) cannot measure pressure. Gap between sensors (dead zone): 0.2mm to 1.0mm

However, dead zones are not accurately represented in sensor measurement graphs.

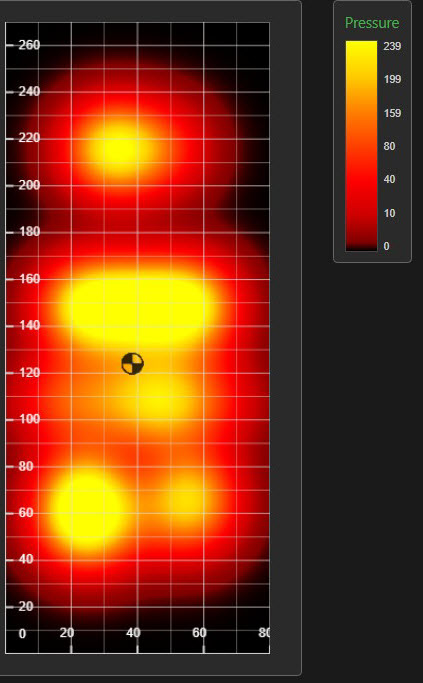

▲ Sensor heatmap

The above is a heatmap graph where the areas between sensors appear interpolated.

These are interpolated values (or represented values)—not actual measurements, but computed approximations.