Tensile Force Measurement

FSR sensors fundamentally measure compressive force (pressing force). However, with proper jig structure design, tensile force (pulling force) can also be measured.

Measurement Principle

Limitations of Direct Measurement

FSR sensors operate on the principle that resistance changes when the resistive material between two electrodes is compressed. Therefore, pulling force cannot be measured directly.

Indirect Measurement Method

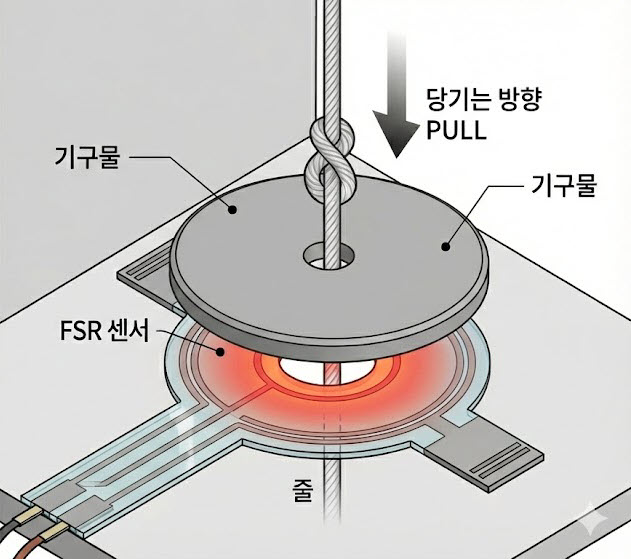

A structure that converts pulling force into pressing force is used.

Conversion Principle:

Tensile Force → Jig Structure → Compressive Force → FSR Sensor

Jig Design Example

A structure where pulling one side of a lever causes the other side to press the sensor.

Use Cases

Grip Detection

- Measuring the force of pulling a handle

- Door handles, levers, handlebars, etc.

- Verifying safety device activation

Precautions

- Indirect measurement: Since tensile force is not measured directly, errors may occur

- Jig precision: Jig manufacturing precision directly affects measurement accuracy

- Friction/Wear: Friction and wear of moving parts affect measured values

- Calibration: Calibration of the entire system including the jig is required

- Limited application: Dedicated load cells are recommended for precise tensile force measurement